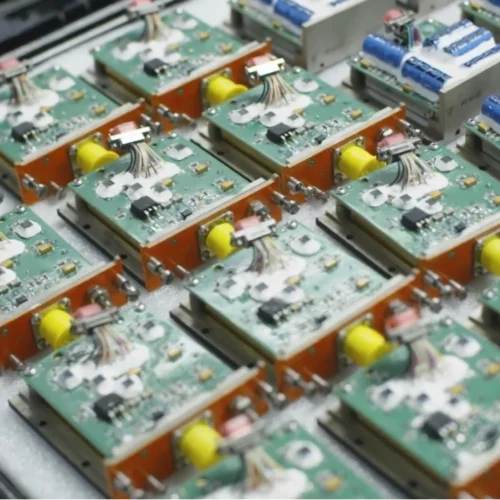

Box Build Assembly & Ball Grid Array (BGA)

Complete System Integration, Precision Assembly

Our box build capabilities include full electromechanical assembly, enclosure integration, and cable routing.

Complete system and sub-assembly builds

Expertise in BGA and Micro BGA placement and rework

Automated pick-and-place technology for consistent quality

FAQs

Our box build assembly includes system-level integration, enclosure assembly, cable and wire harnessing, PCB installation, sub-assembly integration, functional testing, and final packaging.

Yes. We offer scalable solutions to meet the needs of both prototype runs and full-scale production, with flexible manufacturing lines and quality assurance at every stage.

Absolutely. We collaborate closely with clients during the design phase, offering DFM (Design for Manufacturability) input, enclosure design, component layout, and testing strategy development.

Each unit undergoes multi-stage testing and inspection, including continuity checks, functional testing, and final verification. We adhere to industry standards such as IPC-A-610 and ISO certifications.

Yes. We handle final packaging, labeling, warehousing, and global shipping—including drop shipment and just-in-time (JIT) delivery services.

Request a Personalized Consultation

Partner with Realtime Technologies to bring your ideas to life. We offer expert guidance in design, manufacturing, and compliance. Share your needs, and we’ll deliver a tailored solution.