Conformal Coating

Protective Coatings for Harsh Environments

Extend your PCB’s lifespan and reliability with our professional conformal coating services.

Spray, brush, selective, and robotic coating techniques

Moisture, dust, and corrosion protection

Multiple coating material options tailored to your use case

FAQs

Conformal coating is a protective layer applied to printed circuit boards (PCBs) to shield them from moisture, dust, chemicals, corrosion, and temperature extremes. It ensures long-term reliability and performance, especially in harsh environments.

We provide various types of coatings including acrylic, silicone, urethane, epoxy, and parylene—each selected based on your application's environmental, mechanical, and electrical requirements.

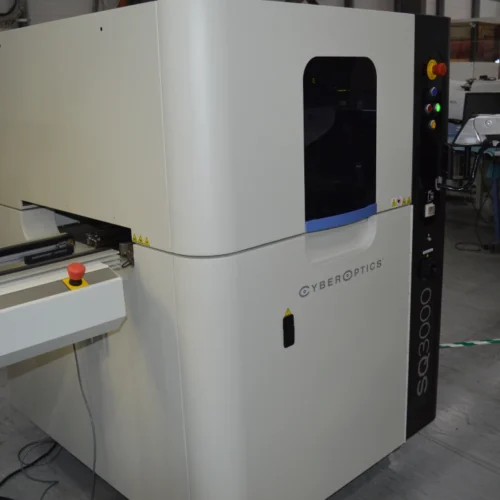

We use multiple application methods such as brush, dip, spray, and automated selective coating systems to ensure precision coverage and minimal masking requirements.

Yes. All coated assemblies undergo thorough visual inspection under UV light, as well as thickness testing and adhesion verification to ensure full compliance with IPC-CC-830 and customer specifications.

Absolutely. We offer safe and effective coating removal services for rework or repair, using techniques appropriate to the type of coating without damaging the PCB or components.

Request a Personalized Consultation

Partner with Realtime Technologies to bring your ideas to life. We offer expert guidance in design, manufacturing, and compliance. Share your needs, and we’ll deliver a tailored solution.