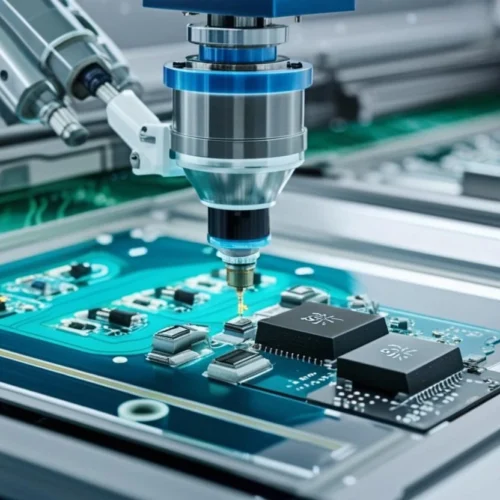

PCB Assembly & Scalable Production

Custom Assembly Solutions for Every Production Stage

At Realtime Technologies, we tailor our manufacturing workflows to meet your exact specifications—whether you’re developing low-volume prototype batches or scaling up to large-scale production runs.

Our PCB assembly services cover a broad spectrum, from single-sided plated through-hole assembly to complex multi-layered PCBs with Micro Ball Grid Array (MBGA) solutions.

We offer flexible engagement models including:

Comprehensive turnkey solutions

Options for you to supply raw materials directly (free-issue processing)

Partial turnkey services

FAQs

We offer a wide range of PCB assembly services including Single-Sided, Double-Sided, and Multi-Layered PCB assemblies. We also handle complex assemblies involving MBGA (Micro Ball Grid Array), SMT, and Through-Hole technologies.

Yes. Our production setup is fully scalable. Whether you need a small prototype batch or large-scale manufacturing, we customise the process to fit your project’s size, timelines, and complexity.

We support full turnkey, partial turnkey, and consignment (free-issue) models. You can choose to have us handle everything—from sourcing components to final assembly—or provide your own materials for processing.

Our facilities operate under strict quality management systems and comply with IPC standards. Every board undergoes automated optical inspection (AOI), X-ray (for BGAs), and functional testing where required.

Lead times vary based on complexity, volume, and material availability. For standard turnkey prototypes, we can often deliver within 7–10 business days. For larger production orders, we provide timelines during project evaluation.

Request a Personalized Consultation

Partner with Realtime Technologies to bring your ideas to life. We offer expert guidance in design, manufacturing, and compliance. Share your needs, and we’ll deliver a tailored solution.